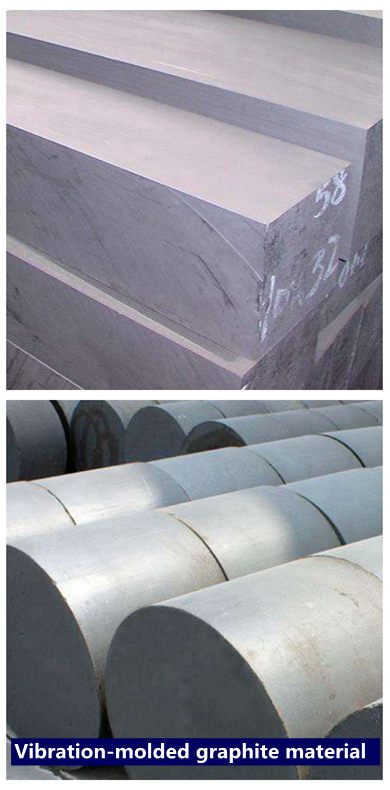

Vibration-molded graphite material

1. Used in silicon carbide furnace, graphitization furnace and other metallurgical furnace, resistance furnace as lining, heat insulation material, conductive material and impermeable graphite heat exchanger.

2. Make all kinds of molds, such as: hot pressing mold, static casting mold, centrifugal casting mold, die casting mold, casting refractory mold, etc.

3. Metal electrolytic cathode, anode material.

Die-molded graphite material

Die-molded graphite products have good electrical conductivity, high temperature resistance, corrosion resistance, high purity, self-lubricating, thermal shock resistance, easy to precision machining and other excellent characteristics. Molded graphite is widely used in aerospace, solar photovoltaic and semiconductor, continuous casting, cemented carbide and electronic mold sintering, spark, glass and other industries.

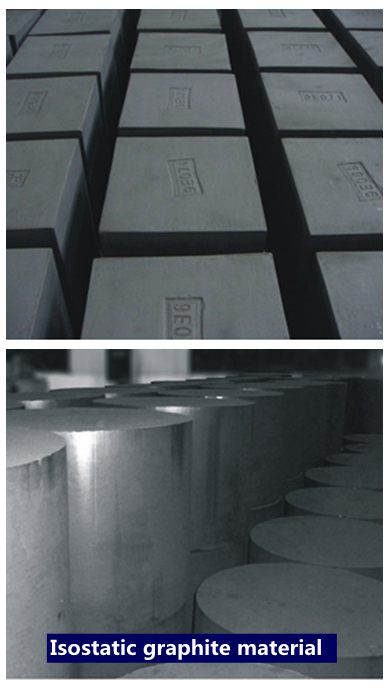

Isostatic graphite material

Carbon products

Petroleum coke (carbon: 85-87%, ash < 1%, size: 0.5-5mm)Needle coke (carbon: 98-99%, density > 2.13g/cm3, ash < 0.15%)

carburant (c > 96.5%, ash < 0.5%, volatile matter < 1%, size: 1-5mm)

Activted carbon(Coal based activated carbon,Coconut shell activated carbon,Pitch based microsphere activated carbon)

Soft / hard carbon (particle: 5.5-15μm, is a kind of soft and hard carbon which is used for high rate power cell, are produced by meso phase precursor and orpolymer pyrolysis process.)

Carbon black (Pigment carbon black, Conductive carbon black, Rubber carbon blacks)

Mesocarbon Microbeads (particle D50: 10-26μm, tap density:1.2-1.5g/cm3, SSA:1-2.4 m2/g)

C/C composite material (bending strength>110Mpa, Compressive strength > 150mpa, using temperature < 2500℃)

Copyright © 2012 Beijing Zhong Tuo Material Technology Co., Ltd. All rights reserved