Graphene-nylon composite yarn

standard: 70D-1000D (D=denier), 1000 grams/spindleultraviolet protection factor(UPF): 75 (much higher than international standard of 40)

far infrared radiated ratio: 0.95 (is higher than 0.88 index of common fabric)

Application: widely used for spin and weave cloth, fabric and textile

Feature: anti-ultraviolet, far infrared radiation, antistatic, good toughness anti-flaming and anti-dripping, mechanical properties and heat resistance is improved significantly, dry heat shrinkage rate is small and size is stable, has antibacterial and anti mite effect, it is considered as next generation of "almighty king" silk.

Graphene thermal-dissipation shim

content: silica gel, graphene, ceramicdensity: 3.3g/cm3 ; hardness: 55 ; grade of flame resistance: V0

range of working temperature: -40~180 °C

permittivity: 7.2 MHz ; electrical resistivity: 1012 Ω.cm

thermal conduction: 8 w/m.k ; breakdown voltage > 6.0 KV/mm

size: 200*400*1mm (thickness can be customized for specific needs)

Application: used for filling the large gap between electronic components and radiators in various electronic products

Graphene-polylactide composite filament

graphene content: 0.0001%, 0.01%, 0.5%wire diameter: 1.75mm±0.03mm / 3.00mm±0.03mm

printing thickness: 0.05mm~0.4mm

optimum printing temperature: 190~220 centigrade

bottom temperature: no heating

feeding speed: 30~60mm/s ; Idling speed: 30~60mm/s

standard: 500 grams/spool

Application: 3D printing

Feature: excellent mechanical properties, strength and toughness are improved a lot, stiffness is increased Shrinkage is low, printing dimensional stability, printing temperature at 190~220 degrees centigrade which is lower than other materials. Good lubricating property, easy out of silk, no plug. Universal printing material which are applicable to mainstream FDM 3D printers on the market.

Graphene-silver composite electroconductive adhesive

component: silver powder, graphene, resin.graphene content: 3% ; Viscosity: 13000

thixotropic index: 4.5 ; particle size < 10 μm

density: 3.8 g/cm3 ; shelf life, (-5℃): 6 month

solidify condition, (150℃): 60 min ; shear strength, (25℃): 21 Kg/die

electrical resistivity: 0.0002 Ω*cm

thermal conductivity, (120℃): 9.5 W/mK ; thermal expansivity: 55 ppm/℃

temperature of thermal decompositio >300 ℃ ; appearance: silvery paste

Application: used for bonding and conduction of PIN pin, metal substrate, electrode surface, antenna, semiconductor components and antenna sensor.

Feature: Low electrical resistivity, stable quality good bending resistance, anti-oxidation, good thixotropy resistance to heat and humidity, comply with RoHS - Restriction of Hazardous Substances, low volatility, long service cycle.

Graphene electromagnetic shielding foam

prepared with CVD methodsize: 150 x 150mm, 200 x 300mm

primary: 95% graphene

auxiliary: 5% PDMS (polydimethylsiloxane)

density: 0.085g/cm3

electromagnetic shielding value: 25dB (8-12GHz)

appearance: black; sponge; flexible, can be folded arbitrary

Application: electromagnetic shielding

Use method: wrap electromagnetic radiation object

Graphene Pressure Transducer (equipped with electric wire, terminal)

working voltage: 3-5V, hysteresis < 5%, drift < 6%,working temperature: -50 - +50℃

response time < 10ms

pressure range: 0-50kgs (optional interval 0-5kg, 6-20kg, 21-50kg)

size: transducer outside diameter-46mm / perception area diameter-40mm

length is 80mm, thickness is 0.24mm

Features: since graphene has a strong surface chemical activity and is suitable to be used as a sensor material, it's detection sensitivity is significantly higher than existing materials. It is ultra thin, ultra flexibility, ultrahigh sensibility, induction area large

Application: sports field-foot pressure test, step counting and other functions health field-measuring blood pressure of human body, internal tissue pressure, cushion sensor, off-bed monitoring sensor, product design and evaluation-interface pressure testing and evaluation safety monitoring, industrial detection, innovative design and scientific research experiments.

Usage: ensure voltage stability, propose maximum electric current is 2.5mA

Graphene thermal-dissipation silicone grease

components: silica resin, graphene, ceramicminimum interface thickness: 0.1mm ; thermal conductivity: 8w/m.K

density: 3.3g/cm 3 ; specific heat capacity: (J/g. K) 1.1

extrusion rate: 15g/min ; volatility < 0.01% ; temperature resistance range(C): - 50~200

dielectric strength > 5.0 Kv/mm ; volume resistivity: 1013 Ω.cm

Use method: by hand or dispensing machine

Features: it is a silicone resin based soft thermal conductive gap filling material. which is filled between electronic components that need to be cooled and radiator to make them close contact, quickly and effectively reduce the temperature of the electronic components, so as to prolonging the service life of the electronic components and improve their reliability. The gel with high thermal conductivity, low interfacial thermal resistance, good thixoplasticity, excellent wettability and softness, no stress, no settlement, no flow, can be compressed to the thinnest 0.1mm, can fill any uneven gap.

Application: used for filling the small gap between electronic components and radiators in various electronic products

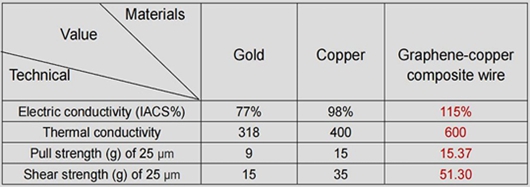

Graphene-copper composite wire

thin layer of graphene is grown on the surface of copper wire by CVD method.the wire diameter is 0.15mm / 0.3mm / 0.6mm / 1mm, 1-50 meters per roll

Feature: take advantage of superconducting properties of graphene, compared with ordinary copper wire, signal transmission capacity is improved by 15% , as well as decrease the signal loss, meanwhile, due to the thermal conductivity of graphene, the heating temperature of copper wire can be significantly reduced by 20%. The earphone cable made of graphene-copper composite wire has excellent acoustic characteristics, which can make the sound frequency response range wider, the transition between high and bass more natural. reduce distortion.

Application: used for earphone cable, signal wire. signal transmission between internal modules of computers, smart phones, precision instruments and other equipment.

Graphene-polymer composite

thermal conductivity: 8-15w / (m · K)thermal emissivity > 0.85

shrinkage: 0.2-0.4%

sturface resistance: 5-15 Ω

Feature:

1. Lightweight: the density is more than 30% lower than that of aluminum, is suitable for injection molding or compression molding, there's no need for secondary processing, and is easy to make complex shape, can markedly reduce the weight of lamps.

2. Excellent heat dissipation effect: the thermal conductivity is much higher than that of traditional heat conducting materials, and the thermal radiation coefficient is far superior to all kinds of metals quickly export and radiate the heat source to the external medium, can replace aluminum in all kinds of heat sinks and radiators.

3. Durable: super weatherproof performance, acid and alkali resistance, anti corrosion, suitable for all kinds of waterproof design, very small expansion coefficient, flame retardancy, adapt to a variety of corrosive gas environments. Wide application and long service life.

4. Easy processing and molding: it is suitable for injection molding or compression molding, there's no need for secondary processing, and is easy to make complex shape.

Application: used for manufacturing various heat dissipation lampshades, radiators and heat dissipation parts

Graphene-HDPE composite roller

This is a kind of composite roller which is made of HDPE added with grapheneFeature:

1. Long service life:

Under the same industrial and mining conditions, it is more than 5 times that of ordinary steel rollers and 2-3 times that of ordinary non-metallic rollers; at the same time, in complex working environments, it will not be damaged by corrosion like metal materials.

2. High wear resistance:

With the help of the excellent mechanical properties and mechanical properties of nano Graphene, the wear resistance and impact resistance of HDPE idler after composite are significantly improved and the service life of the roller is greatly extended.

3. Impact resistance:

Composite Graphene roller, with excellent impact resistance, are the only conventional idlers known in the market that can replace the buffer roller: they can be directly used at the coal falling point or impact point of the belt, solving many problems of non-metallic idlers that are fragile due to impact.

4. Lightweight:

It is one-third of the weight of the steel roller, making it easy to install and maintain, greatly reducing the labor intensity of workers.

5. Zero damage to the belt:

Good self-lubrication, preventing the surface of the roller from scaling; no knife stabs, no belt damage, reduced belt wear, and extended belt service life.

6. Low noise:

Below 75 decibels, significantly reducing noise and improving the working environment caused by belt noise.

7. Energy saving:

The running resistance is small, and through actual measurement, it can save more than 10% of electricity bills.

Appliction: used for belt conveyor machinery

Graphene-PP(Polypropylene) composite

graphene content: 15%melt flow rate: ~4.5 g/10min

notched Impact Strength >126 J/m

drying temperature: bake for 2 hours at 100℃

injection temperature: 210℃-220℃

Feature:

toughness is better

rigidity is higher

processability is better

impact resistance increased

Application: widely used in industry areas, such as auto parts, dashboard, steering wheel, handle, container, storage battery shell.

Graphene-ABS composite

graphene content: 15%oxygen index > 24.8%

tensile strength > 40.84MPa

modulus of elasticity > 1360MPa

drying temperature: bake for 2 hours at 90℃

injection temperature: 210℃-220℃

Feature:

with performance of hardness is higher, heat resistance is better.

corrosion resistance enhanced, fire resistance enhanced, antistatic.

Application: widely used for auto dashboard, body outer panel, interior decorative board, sound insulation board, door locks, bumper, ventilation pipe, air conditioning, computer, ABS pipe, ABS sanitary ware, ABS decorative plate, etc.

Copyright © 2012 Beijing Zhong Tuo Material Technology Co., Ltd. All rights reserved